Models for Business and Positive Decision-Making

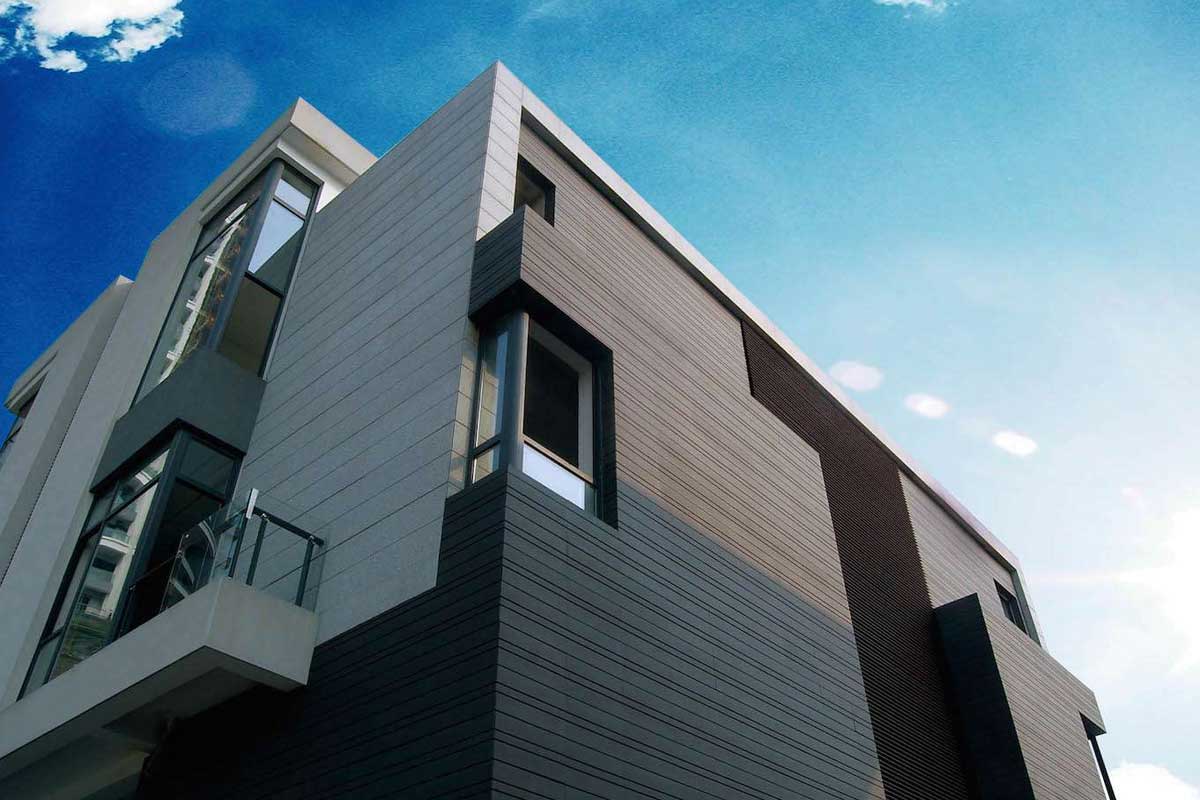

In the contemporary landscape, the imperative for sustainable practices within the realm of construction and development has become increasingly paramount. Embracing an ethos of resilience and positive decision-making, this exploration delves into the multifaceted world of building sustainability. From innovative business models to conscientious choices that contribute to a positive environmental impact, this journey aims to uncover the strategies and practices that pave the way for a more ecologically conscious and enduring future in the construction industry. Join us as we navigate the intricate intersection of business acumen and environmental stewardship, unraveling the threads of sustainable building that weave a tapestry of responsible and forward-thinking development.

In recent years, companies like GreenBuild Innovations have epitomized the fusion of business acumen and environmental responsibility. This sustainability-focused enterprise has not only adopted cutting-edge business models that prioritize eco-friendly materials and energy-efficient designs but has also made positive decisions at every stage of its projects. From sourcing locally produced, renewable materials to implementing green construction technologies, GreenBuild Innovations serves as a beacon of success in the sustainable building landscape. Through their endeavors, they not only contribute to a reduced carbon footprint but also showcase the economic viability and long-term benefits of embracing sustainability in the construction industry. The experiences of such trailblazing companies underscore the significance of our exploration into sustainable building models and positive decision-making for a resilient and environmentally conscious future.

Sustainable Construction: Business Models and Positive Decision-Making

The global trend toward sustainable building is on the rise, propelled by government policies and business models that draw inspiration from the principles of the circular economy. In this evolving landscape, the ceramics industry has strategically carved a niche for itself by dedicating resources to sustainable research and development. This deliberate commitment not only aligns with the prevailing global shift towards sustainability but also positions the ceramics sector as a successful contributor to environmentally responsible practices in construction on a worldwide scale.

The significance of a product’s life cycle has become paramount in defining its sustainability. Mere use of natural or recycled materials is no longer sufficient to label a product as “environmentally friendly.” The understanding of impacts has advanced to a level where it is universally recognized that a product’s life cycle commences with the acquisition of raw materials – or even earlier, during the decision-making process on how and where to obtain them. This cycle extends until the product is fully decommissioned or its materials are repurposed through recycling value chains.

Rather than focusing solely on individual products, a comprehensive life cycle assessment is imperative, particularly when evaluating entire building systems and their energy consumption. This assessment encompasses:

- Production of construction materials and components.

- Transportation of materials from production facilities to the building site.

- Construction processes.

- Operation, including considerations for heating, hot water production, etc.

- Building demolition.

- Positive contributions from material and component recycling.

In the selection of materials and components for a project, it is essential to identify the interrelationships of each element within the building system and assess its role in the overall energy balance. Opting for ceramics aligns with a holistic design approach that considers the entire life cycle of the project. This approach represents the only responsible vision for shaping the future of the spaces and territories in which we reside.

Ceramics: A Low-Impact Supply Chain

In the realm of finishing materials, ceramic tiles and slabs stand out for their notably lower environmental impact, a result of the extensive technological advancements, plant design, and production innovations within the Italian ceramic industry. This sector has demonstrated a commitment to sustainability by efficiently recycling the majority of waste generated during production, a notable achievement given the energy-intensive nature of the process. This progressive approach has significantly reduced energy consumption compared to previous years.

Transitioning to the subsequent phase in a tile’s life cycle—its installation—the materials used for the installation and grouting carry negligible toxicological concerns. This holds true as well for the demolition of tiling, where the resulting rubble can be safely reintegrated into the environment without posing significant risks.

Equally noteworthy are the technical performances and outstanding durability of ceramic tiles. These characteristics, coupled with the industry’s eco-conscious practices, position ceramics as a surface covering material that adeptly meets the demands of contemporary performance standards. In essence, ceramics emerge as a sustainable choice, aligning with environmental responsibility throughout their life cycle.

Mindful Administration by the Manufacturer

It has been highlighted that the ceramics industry, as a whole, has been dedicated to diminishing its energy consumption and minimizing its reliance on natural resources over the years. Take Tile Optima, for instance, a company that has consistently demonstrated a robust commitment to mitigating the environmental footprint of its production operations. This commitment is transparently documented in an annual sustainability report spanning the last twelve years, which outlines noteworthy strategies, investments, research endeavors, and the collective contributions of its workforce.

From the implementation of a new photovoltaic plant to innovative processes for recovering production waste, Tile Optima has succeeded in maintaining resource efficiency despite the expansion of its Italian production capacity. Notably, in contrast to the environmental impacts associated with the production of natural materials like stone or timber, the manufacturing of Tile Optima’s porcelain stoneware, branded as Made in Tile Optima, has negligible effects on territorial biodiversity.